Cleanroom Jib Crane for Semiconductor Industry

The clean room jib crane is a lifting equipment specially designed for dust-free environments. Its unique structure and functions make it play a decisive role in the semiconductor industry.

The clean room jib crane is a lifting equipment specially designed for dust-free environments. Its unique structure and functions make it play a decisive role in the semiconductor industry. This kind of equipment can not only effectively ensure the cleanliness of the production environment, but also improve production efficiency and reduce production costs.

Product design advantages

The design of the clean room jib crane fully takes into account the extremely high cleanliness requirements of semiconductor production. Its compact structure and smooth surface prevent dust accumulation and are easy to clean, thus minimizing the generation of dust and particulate matter. In addition, the equipment is also equipped with high-efficiency filters and clean air supply systems, which can continuously provide clean air to the working environment and ensure high cleanliness inside the clean room. This design enables the clean room jib crane to effectively avoid product quality problems caused by dust contamination in semiconductor production.

Application of clean room jib crane in semiconductor industry

It is mainly used for the handling and positioning of materials, such as the lifting and transfer of precision components such as silicon wafers and wafers. Because of its easy operation and high accuracy, it can achieve smooth lifting and movement of items, so it can greatly improve production efficiency and product quality. In addition, clean room jib cranes are also suitable for short-distance, frequently used intensive lifting operations, and can meet the high-frequency, high-precision material handling needs of semiconductor production lines.

Main feature

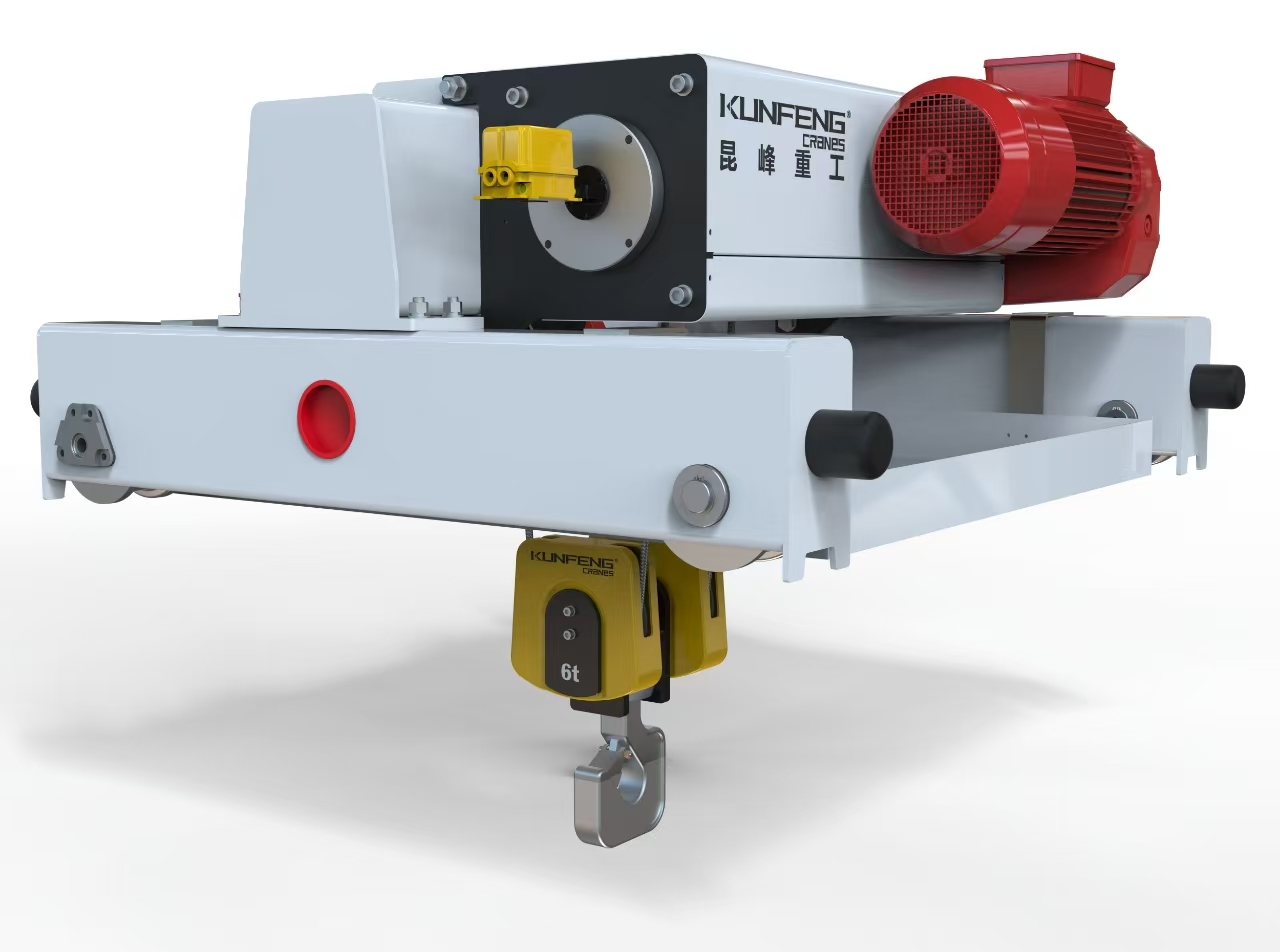

● Using a highly reliable electric hoist as the power source can ensure the stable operation and long-term use of the equipment.

● The equipment's reasonable structural design makes it occupy a small area and enable efficient material handling in a limited space.

● Precise operation can be achieved through simple control devices, reducing operating difficulty and cost.

● Using high-strength materials and reliable structural design, it can withstand the lifting and handling of heavy objects.

● It has a certain degree of flexibility, and its rotation range can be adjusted according to actual needs, which can meet the material handling needs in different scenarios.