Aluminum Floor Mounted Workstation Jib Crane

Aluminum floor mounted workstation jib crane is a lifting equipment suitable for workstations, production lines and other places that require frequent lifting.

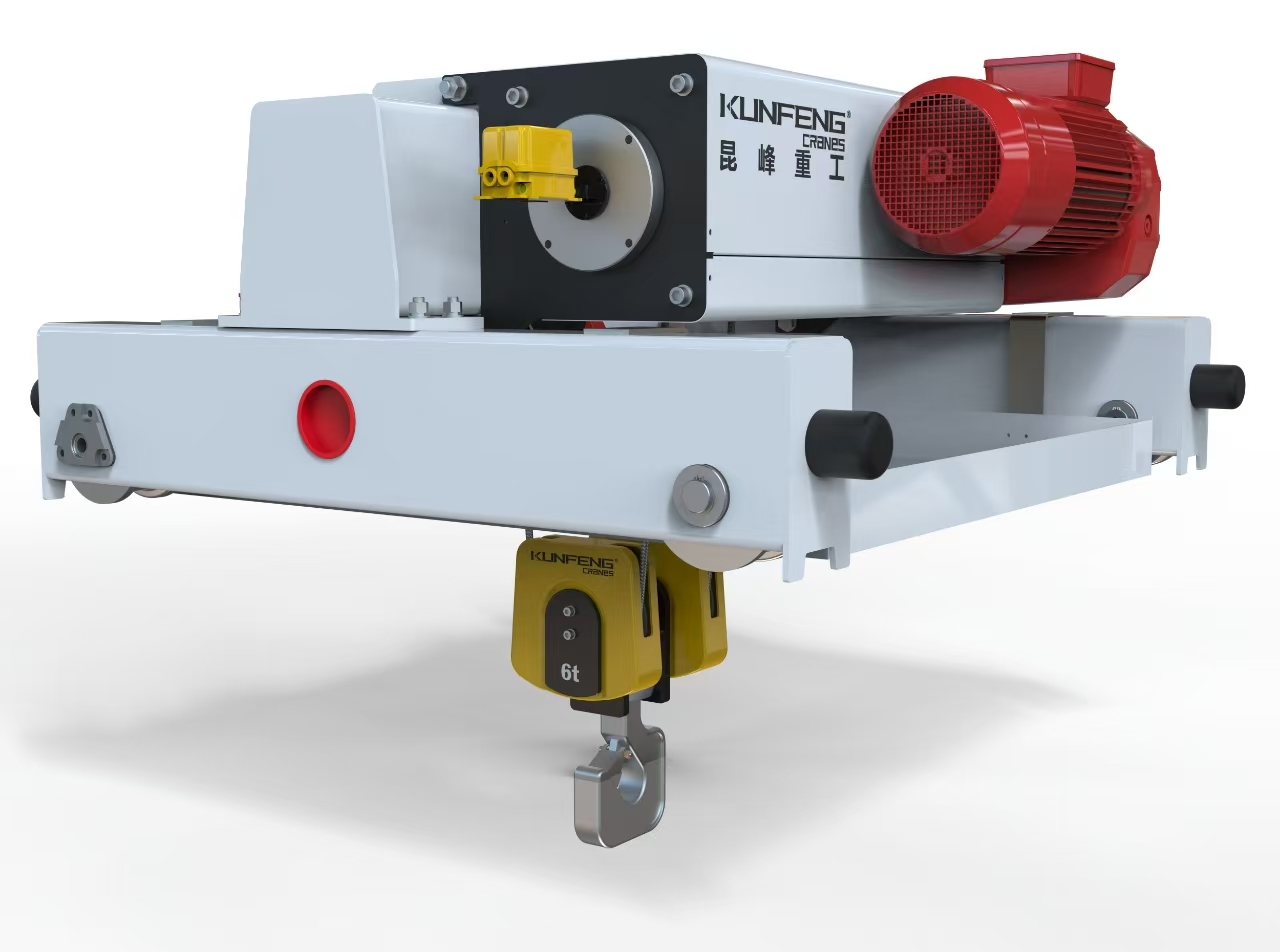

Aluminum floor mounted workstation jib crane is a lifting equipment suitable for workstations, production lines and other places that require frequent lifting. It is made of aluminum alloy and is lightweight, corrosion-resistant, and easy to clean. The crane usually consists of a floor standing frame, a jib and an electric hoist. The swing arm can rotate 360 degrees, and the electric hoist can rise and fall along the swing arm for lifting and carrying goods.

Working principle

When users need to move goods, they only need to set the lifting height and rotation angle through the control system, then start the electric hoist, and the goods will be quickly lifted to the specified height. Then, the user can manually or automatically control the rotation of the arm to transport the goods to the designated location. During the entire process, the control system will make real-time adjustments according to the actual situation to ensure the stable and safe operation of the crane.

Structural features

Aluminum floor mounted workstation jib crane is mainly composed of jib, lifting mechanism, control system and other parts. The swing arm is made of high-strength aluminum alloy material, which is lightweight, corrosion-resistant, and beautiful. The lifting mechanism includes electric hoists, wire ropes, pulleys and other components, which can achieve rapid lifting and precise positioning of goods. The control system uses advanced microcomputer control technology to realize intelligent and automated operation of the crane.

Application areas

Aluminum floor mounted workstation jib crane is widely used in various industrial production environments, such as automobile manufacturing, mechanical processing, electronic assembly, warehousing and logistics, etc. In these fields, cranes can greatly improve the efficiency and accuracy of material handling, reduce workers' labor intensity, and improve production efficiency. At the same time, due to its compact structure and small footprint, the aluminum floor mounted workstation jib crane is also suitable for installation in production workshops or warehouses with limited space.

Advantage analysis

● It can realize rapid lifting and precise positioning of goods, greatly improving the efficiency and flexibility of material handling.

● The structure is compact and the floor space is small, effectively saving production space.

● The use of advanced microcomputer control technology can realize intelligent and automated operation of the crane, greatly improving the safety and reliability of operation.

● Each component is reasonably designed and easy to maintain, which reduces the company's operating costs.