Food Grade Free Standing Jib Cranes

Food grade freestanding jib cranes are made of stainless steel and designed to meet the hygiene standards of the food industry. They provide efficient, safe and flexible material handling solutions and are widely used in food production lines and storage environments.

The food grade free standing jib cranes are high-quality lifting equipment designed for the food processing and packaging industry. Made of food grade stainless steel, it is corrosion-resistant and easy to clean, ensuring that it is used under strict hygiene standards. The free standing support design does not need to be fixed to the building structure, and has the advantages of flexible installation and mobility. It is widely used in food production lines, warehousing and distribution centers.

The core advantages of food grade jib cranes

Food grade materials, safe and worry-free

● Made of stainless steel, it has excellent anti-corrosion and anti-rust performance. It has passed FDA, HACCP and other food hygiene certifications and can directly contact the food processing environment.

Free standing structure, flexible installation

● Without relying on the factory wall, the free standing base design can be quickly deployed at any position in the workshop, saving space while meeting the needs of multi-station collaborative operations. The 360° rotating jib covers a radius of 3-6 meters, with a load range of 50kg-2000kg, which can easily adapt to various scenarios such as sorting, filling, and packaging.

Stability and safety are guaranteed

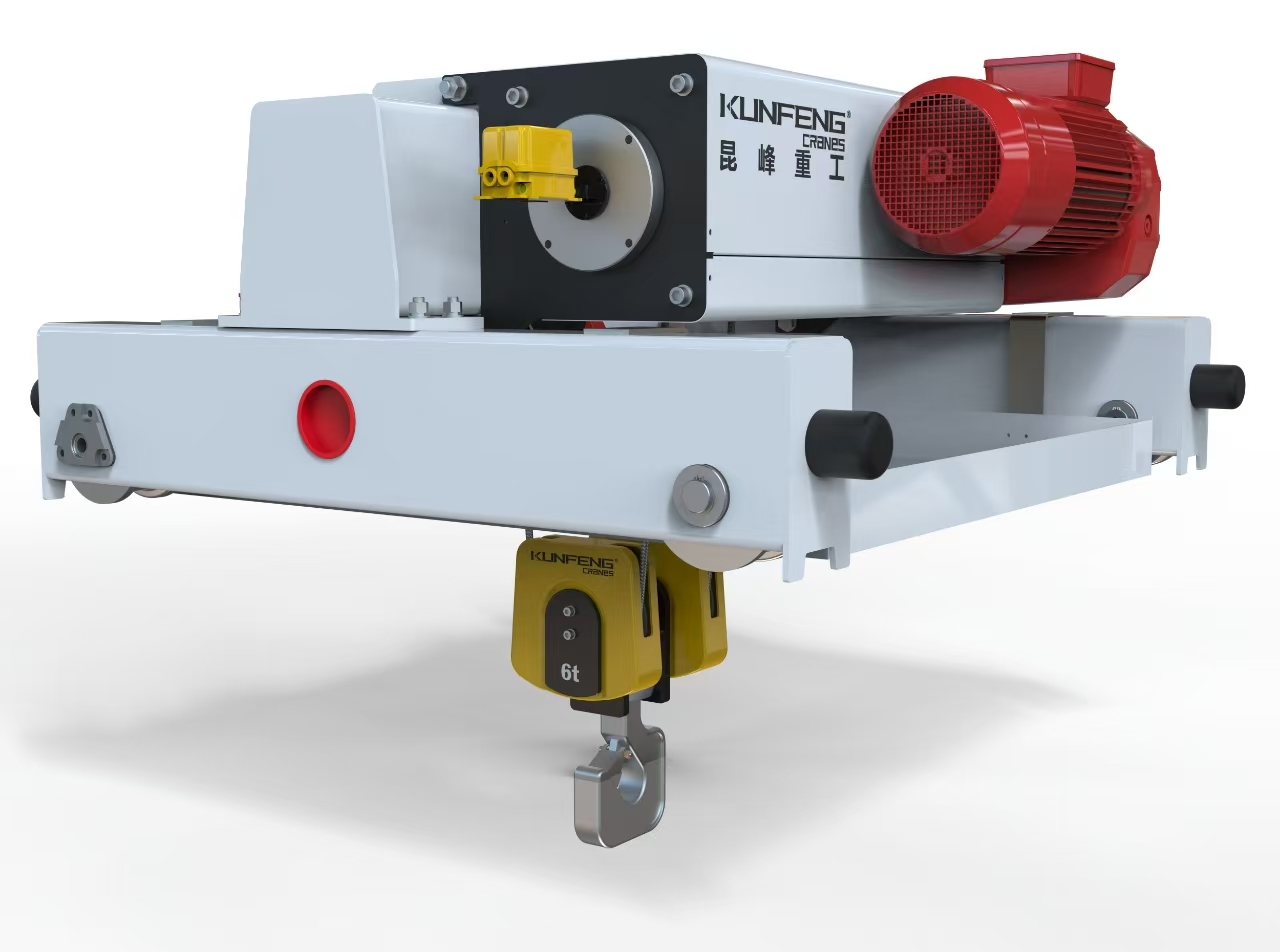

● The use of high-precision electric or manual hoist system ensures that heavy objects are lifted smoothly and accurately, greatly improving work safety and reducing the labor intensity of workers.

Optimized design for clean production

● IP65 protection level eliminates the risk of lubricant leakage; removable hooks and accessories facilitate deep cleaning and quick replacement; optional antibacterial coating to meet the needs of GMP workshops or sterile environments.

Application scenarios of food grade free standing jib cranes

● Food processing: meat sorting line, dairy canning, and baking line hoisting.

● Central kitchen: large-scale cooking equipment handling, raw material storage and turnover.

● Pharmaceutical production: clean area material transfer, aseptic packaging line precise positioning.

● Beverage industry: bottled water filling, cans stacking and efficient operation.

Why choose KUNFENG jib cranes

● Strict quality control: Each equipment undergoes 72 hours of load testing and health and safety testing before leaving the factory.

● Fast delivery: standardized module production, 7-15 days of extremely fast installation and commissioning.

● Strong safety: precise lifting system ensures safe operation and reduces work injuries caused by improper lifting.

● After-sales service: Provide remote technical support and cleaning solutions.

Contact KUNFENG now to get a free workshop layout plan and exclusive quotation. We will provide you with the most suitable lifting solution.

Prev: Wall Mounted Slewing Jib Crane

Next: none!!