Pharmaceutical Cleanroom Hoist

Clean room hoists and lifting equipment for the pharmaceutical sector require very stringent controls for contaminants. The cleanroom cleanliness level is high(Class 100-10000,ISO 5-8, Class A-D), the standard pharmaceutical cleanroom systems need to meet the requirements of GMP,FDA, WHO and other pharmaceutical standard.

Clean room hoists and lifting equipment for the pharmaceutical sector require very stringent controls for contaminants. The cleanroom cleanliness level is high(Class 100-10000,ISO 5-8, Class A-D), the standard pharmaceutical cleanroom systems need to meet the requirements of GMP,FDA, WHO and other pharmaceutical standard.

Key Requirements for Clean Room Hoists

Material Compatibility:

• Hoists must be constructed from materials that do not emit particles or off-gasses that could contaminate the clean room environment. Stainless steel and non-corrosive alloys are preferred for their resistance to chemical cleaning agents and sterilization processes.

Smooth Surfaces and Easy Cleaning

• The design should eliminate crevices and protrusions where dust or microorganisms might accumulate. Smooth surfaces facilitate easy and thorough cleaning, ensuring no contaminants are harbored.

Anti-Microbial Coatings

• Some hoists may be treated with anti-microbial coatings to inhibit the growth of bacteria and fungi, further enhancing the clean room's sterility.

Sealed Components

• All moving parts, electrical components, and seals must be hermetically sealed to prevent the ingress of particulates and to contain any lubricants that could contaminate the environment.

Lubrication

• Food-grade or FDA-approved lubricants are used to minimize the risk of contamination. Some hoists may feature self-lubricating components to reduce maintenance and the need for external lubrication.

Applications in Pharmaceutical Clean Rooms

Pharmaceutical clean room hoists are utilized in various tasks, including:

Material Handling

• Moving raw materials, containers, and finished products between different processing stages.

Equipment Installation and Maintenance

• Lifting and positioning equipment during installation and maintenance activities.

Sterilization Processes

• Transferring items in and out of autoclaves and sterilization chambers.

Packaging and Distribution

• Assisting in the packaging and distribution of pharmaceutical products while maintaining the clean room's controlled environment.

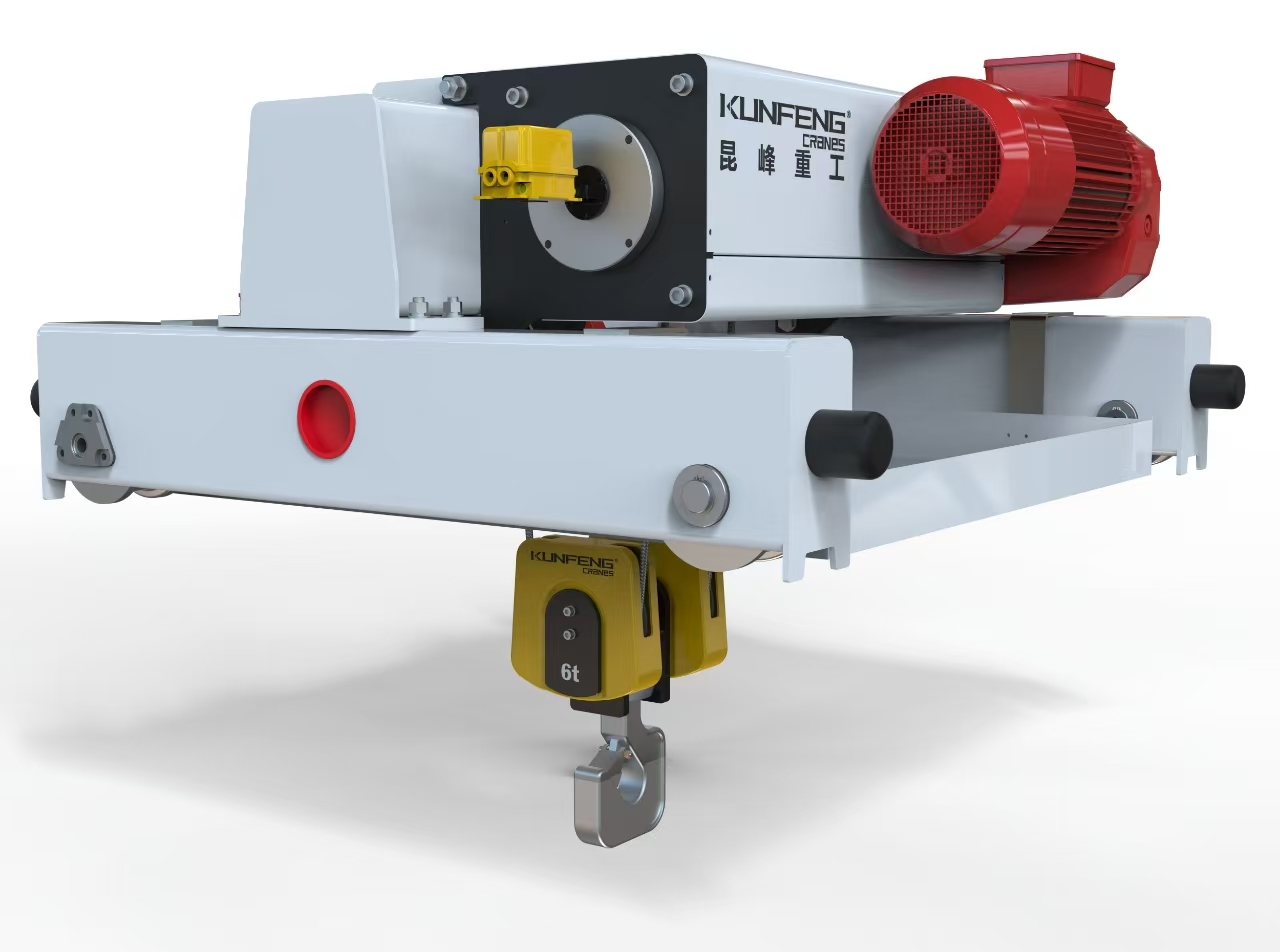

KUNFENG Cranes have experience of working with pharmaceutical manufacturing companies to design, manufacture and supply quality, certified cleanroom hoists. Our hoists and lifting mediums feature 304 and 316 stainless steel housing and components, including wheels, drum and hook block, and are also available with Dyneema Belt. For more information about the cleanroom hoist, free to contact us to obtain relevant data.