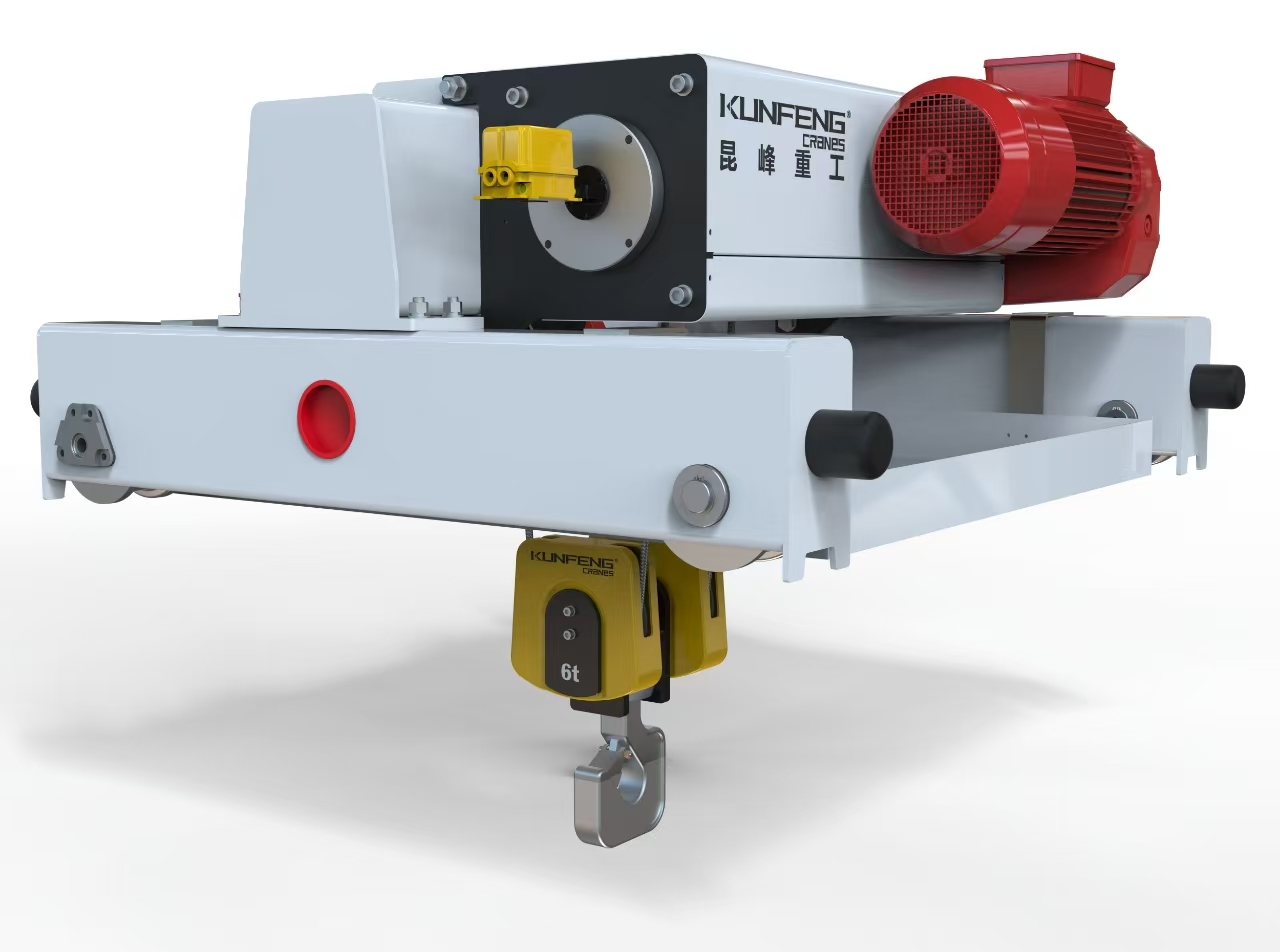

3 Tons Double Hook Chain Electric Hoist

In heavy material handling and precision installation operations, the 3-ton double hook chain electric hoist has become an indispensable lifting equipment for industrial, construction, shipbuilding and many manufacturing fields with its excellent performance, efficient operation and excellent safety assurance capabilities.

In heavy material handling and precision installation operations, the 3-ton double hook chain electric hoist has become an indispensable lifting equipment for industrial, construction, shipbuilding and many manufacturing fields with its excellent performance, efficient operation and excellent safety assurance capabilities. This article will detail the core characteristics, technical advantages and significant benefits of the 3-ton double hook chain electric hoist in practical application, showing how it can become a helpful assistant to improve work efficiency and ensure operation safety.

Core Features and Technical Advantages

* Flexible and Efficient Double Hook Design : the most significant feature of 3 tons double hook chain electric hoist is equipped with two independently operated hooks, each hook can withstand up to 3 tons of load. This design greatly increases operational flexibility, allowing for simultaneous handling of two loads of different weights or positions, or for precise alignment of large components, significantly increasing efficiency and reducing operational cycles.

* High Performance Chain and Drive System: high strength wear-resistant chain is used to ensure stable and reliable under heavy load conditions and extend service life. Combined with high-efficiency motor and precision gear reducer, it provides smooth and stable lifting force, which can maintain the stability of power output even in continuous operation, reduce energy consumption and reduce noise.

* Intelligent Control and Safety Guarantee: Built-in advanced intelligent control system, support for remote operation, with overload protection, emergency stop, limit protection and other safety functions. Through accurate load detection and speed control, overload operation is effectively avoided, operation safety is guaranteed, and accidents are reduced.

* Durability and Environmental Adaptability: The shell adopts high-quality anticorrosive materials to adapt to various harsh environments, whether it is high temperature, low temperature, wet or dusty environment, to ensure the normal operation of the equipment. At the same time, the compact structure design facilitates installation and maintenance, reducing equipment downtime.

Application Scenarios

• Heavy Manufacturing: In the automotive, aerospace, heavy machinery manufacturing, for the handling, assembly and maintenance of large parts, improve the flexibility and efficiency of the production line.

• Building Construction: in high-rise buildings, bridge construction and other projects, used for the hoisting and positioning of prefabricated components, double hook design is particularly suitable for the precise installation of complex structures.

• Logistics Warehousing: In large storage centers, it can effectively improve the loading and unloading efficiency of heavy cargo, especially in scenarios that need to handle cargo in multiple different locations at the same time.

• Shipbuilding and Repair: At the shipyard, the 3-ton double hook chain electric hoists enable the safe and efficient lifting and assembly of large parts to meet the special needs of shipbuilding and ship repair.

Epilogue

With its outstanding load capacity, flexibility, efficiency and excellent safety performance, the 3-ton double hook chain electric hoist is the ideal choice for efficient material handling and precision operations in many industries. If you want to know more about hoists, please contact us for relevant materials.