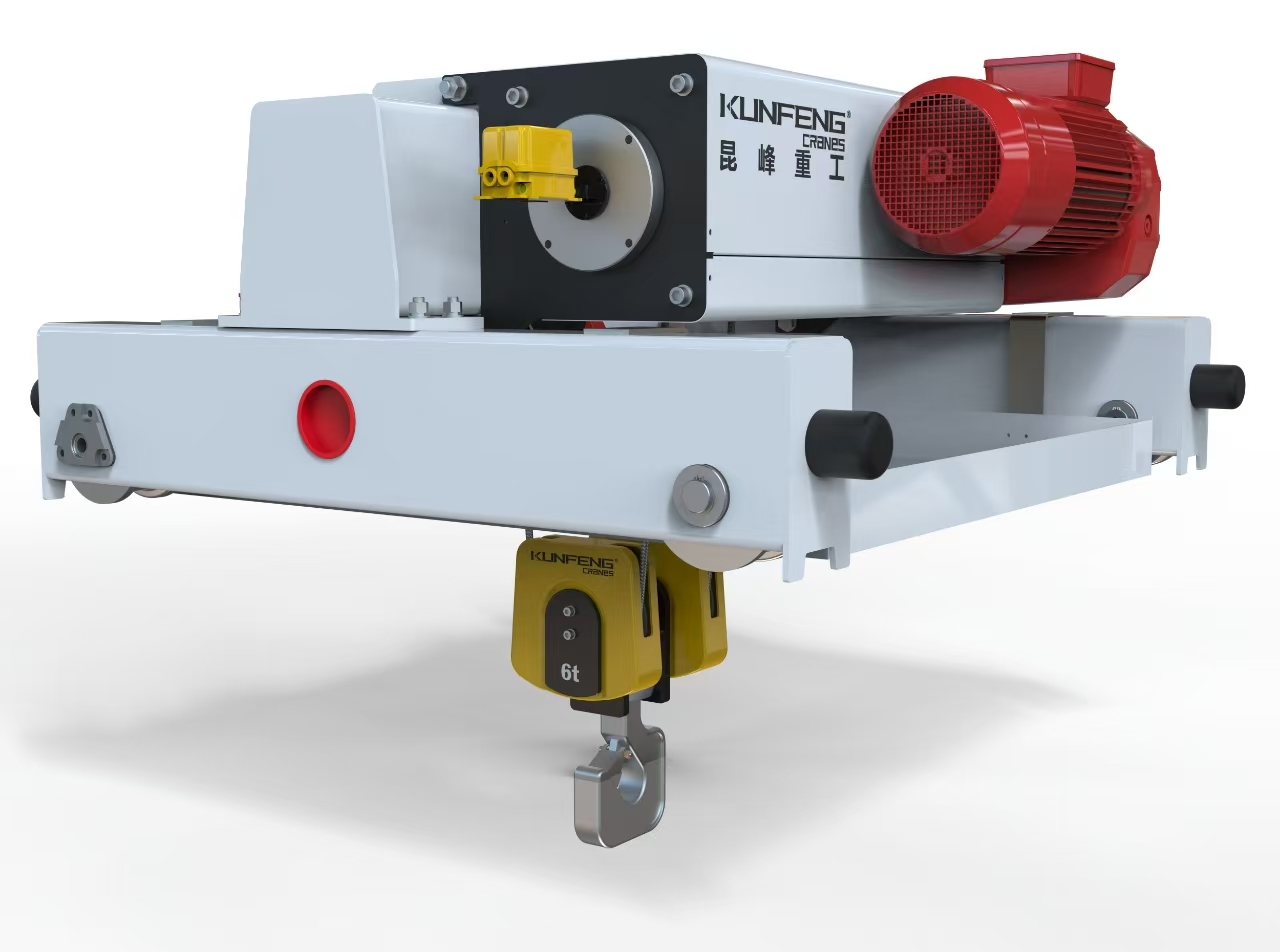

Clean Explosion Proof Electric Chain Hoist

Clean explosion proof electric chain hoist is an ideal equipment for moving heavy objects in explosion proof and clean room environments in controlled workshops, pharmaceutical, chemical and other industries.

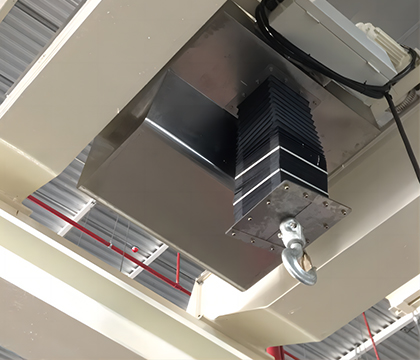

The clean explosion proof electric chain hoist combines the two important functions of cleanliness and explosion proof. It is suitable for industries that require high cleanliness, such as electronic chip manufacturing, pharmaceuticals, bioengineering, etc., and where there are potential explosion hazards such as flammable and explosive gases and dust. . Its outer shell is generally made of high-quality stainless steel or special explosion proof materials, and has excellent sealing properties to prevent electric sparks, static electricity or high-temperature components generated inside from contacting external combustible substances. At the same time, its chains, hooks and other components have been specially treated, which not only have good explosion proof performance, but also avoid the generation of pollutants such as rust and dust to maintain the cleanliness of the working environment.

The difference between clean explosion proof chain hoist and ordinary chain hoist

There are many significant differences between clean explosion proof chain hoists and ordinary chain hoists. Ordinary chain hoists are mainly used in general working environments, focusing on lifting functions and basic safety performance. The clean explosion proof chain hoist is specially designed for special environments. In terms of explosion proof, it uses special explosion proof motors, electrical components and sealing structures, which can effectively prevent the electric sparks and static electricity that may be generated inside from causing the explosion of flammable and explosive materials around it. Ordinary chain hoists do not have this explosion proof design. In terms of cleanliness, the shell, chain and other parts of the clean explosion proof chain hoist are mostly made of materials that are not easy to produce dust and rust, and have good sealing to avoid leakage of internal oil and debris to keep the working environment clean. This is very different from ordinary chain hoists that may generate dust and rust pollution. In addition, the control system of the clean explosion proof chain hoist is more precise, and can achieve more sophisticated and safer operations under complex clean explosion proof requirements.

Design features of clean explosion proof electric chain hoist

● The use of motors with high explosion proof grades enables safe operation in flammable and explosive environments.

● Made of stainless steel or special coating materials to prevent metal particles or other contaminants from entering the clean environment.

● All components are made of corrosion-resistant materials to adapt to the special explosion proof and humid working environment, extending the service life of the equipment.

● It has precise lifting, lowering and positioning functions and can lift heavy objects smoothly.

● The modular structure makes installation, maintenance and replacement of parts easy, reducing maintenance difficulty and cost.

The dual design of explosion proof and cleanliness ensures that the explosion proof electric chain hoist can operate stably and safely in a high-cleanliness, flammable and explosive environment. Its compact, durable structure and efficient performance make it an ideal equipment for moving heavy objects in explosion proof and clean room environments in clean workshops, pharmaceuticals, chemicals and other industries.