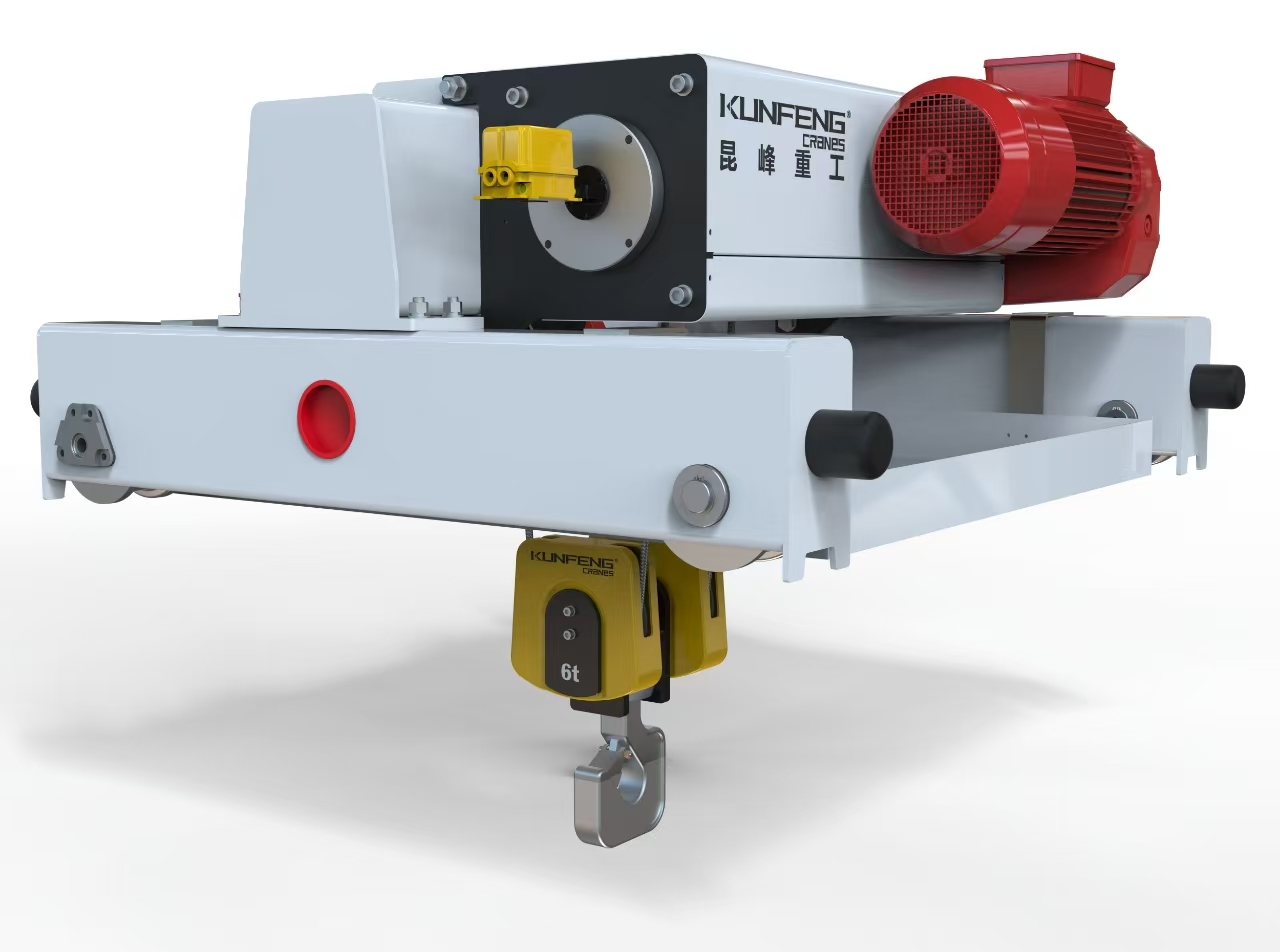

Food Grade Clean Room Electric Chain Hoist

Food grade clean room electric chain hoists are made of high-quality stainless steel or other materials that meet food grade standards to ensure that the equipment will not cause contamination when it comes into contact with food or the food production environment.

Food grade clean room electric chain hoists are made of high-quality stainless steel or other materials that meet food grade standards to ensure that the equipment will not cause contamination when it comes into contact with food or the food production environment. It is anti-corrosive, easy to clean, non-toxic and harmless, and meets the hygiene and safety standards of the food industry. At the same time, the equipment is also equipped with advanced electrical control systems and safety protection devices to ensure stability and safety during operation.

Performance parameters

● Lifting capacity: The maximum weight that can be lifted safely, usually ranging from a few hundred kilograms to several tons.

● Lifting height: The maximum height for lifting materials, which can be customized to meet the needs of different production lines.

● Running speed: including lifting speed and running speed, which are usually adjustable to adapt to different handling needs.

● Power supply: electric drive, needs to be connected to AC power supply to work.

● Material: Made of stainless steel or other materials that meet food grade standards.

Application in food production workshops

● Material handling: used to handle materials such as raw materials, semi-finished products and finished products to reduce the labor intensity of manual handling and improve production efficiency.

● Production line coordination: used in conjunction with other equipment on the production line to achieve precise positioning and rapid delivery of materials and promote the smooth progress of the production process.

● Clean environment maintenance: Its dust-free and oil-free design helps maintain a clean environment in food production workshops and avoid cross-contamination.

Product advantages

● Made of materials that meet food grade standards, it is non-toxic and harmless, easy to clean, and complies with the hygiene and safety standards of the food industry.

● It has efficient handling capacity and stable performance, which can improve production efficiency and reduce labor intensity.

● Customized designs can be made according to the specific needs of food production workshops to meet the requirements of different production environments and working conditions.

● Equipped with advanced electrical control systems and safety protection devices to ensure stability and safety during operation.

● The structure is compact and simple, easy to install, disassemble and maintain, reducing maintenance costs.