DRS Drive Wheel Block System

The DRS drive wheel block system is a walking device used to support equipment and loads. It runs on rails to enable equipment to move on the ground.

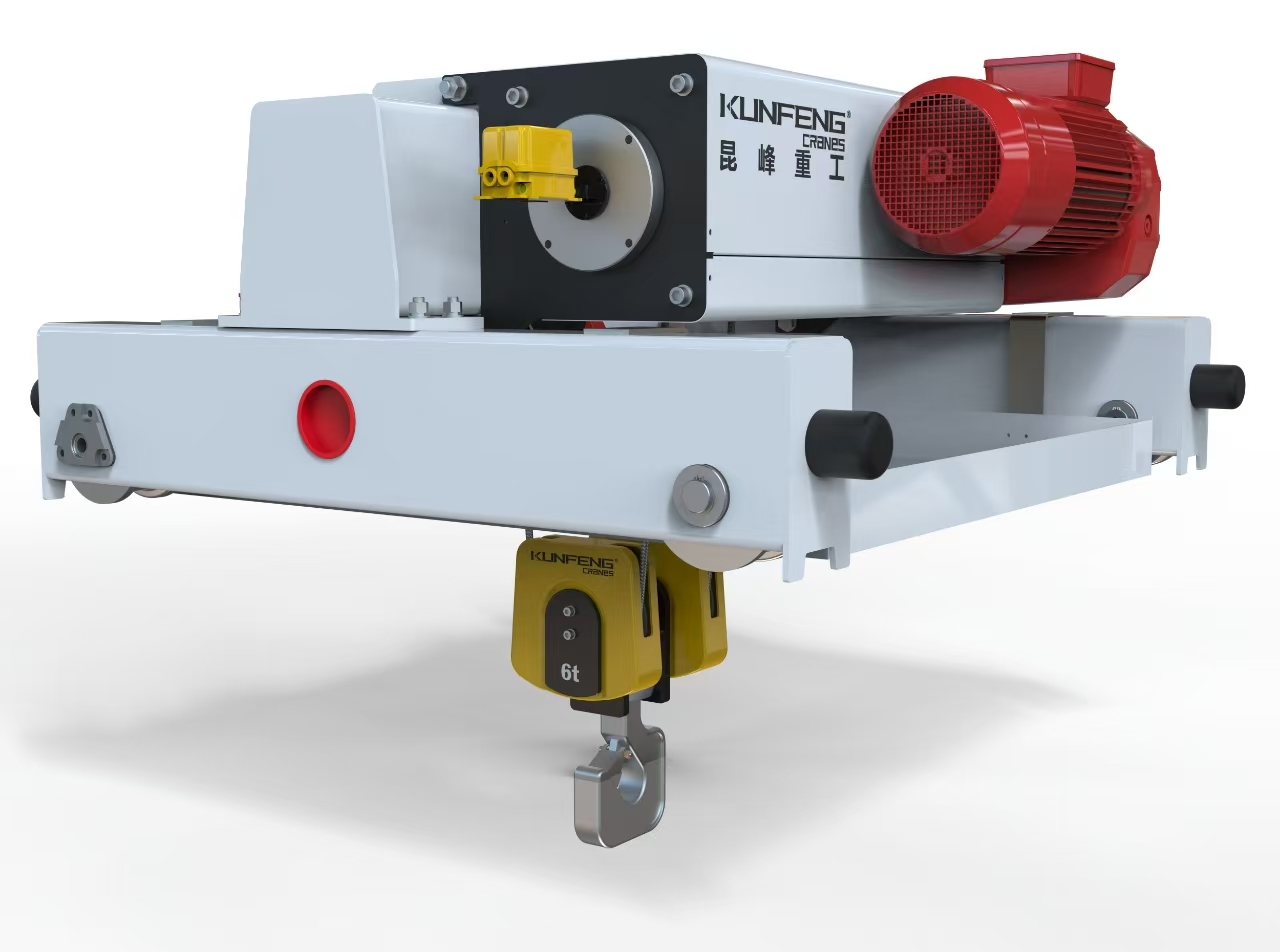

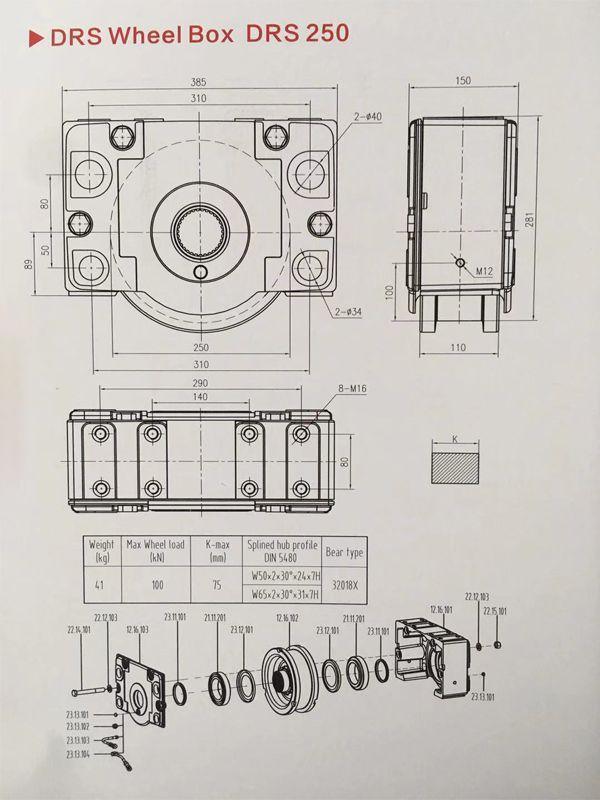

The DRS drive wheel block system is a walking device used to support equipment and loads. It runs on rails to enable equipment to move on the ground. It is mainly composed of wheels, bearings, transmission devices, motors and control systems. Among them, wheels are key components that directly support the weight of the equipment and are usually made of high-strength materials to withstand larger loads. Bearings are used to connect the wheels and the main body of the equipment to ensure that the wheels can rotate smoothly. The transmission transmits the power of the motor to the wheels, driving the equipment to move. The control system is responsible for controlling the operation of the motor to achieve precise position control and speed adjustment.

Features

● It has high strength and wear resistance and can operate stably for a long time in harsh working environments.

● It has the characteristics of low noise and high efficiency, which can effectively reduce the noise level when the equipment is running and improve the operating efficiency of the equipment.

● It has high precision and reliability and can meet the requirements of various complex and delicate work tasks.

● It has the characteristics of easy maintenance, and the replacement of parts is convenient and quick, reducing maintenance costs.

Purpose

DRS wheel block system is widely used in various industrial equipment and machinery, such as cranes, gantry cranes, conveyor lines, etc. In these devices, the wheel block plays a supporting and driving role, allowing the device to move and position smoothly on the ground. At the same time, due to its high accuracy and reliability, the DRS wheel block system is often used in scenarios that require high position accuracy, such as material handling and positioning on automated production lines.

After-sales service

As a professional manufacturer, KUNFENG usually provides complete after-sales services, including equipment installation and commissioning, technical training, repair and maintenance, etc. When equipment malfunctions or problems occur, the after-sales service team will respond promptly and provide solutions to ensure the normal operation of the equipment. This comprehensive after-sales service can not only reduce users' operating costs, but also improve the service life and stability of the equipment.

Non-standard customization

In actual applications, users need to choose the appropriate DRS wheel block system model and specifications according to the specific working environment and task requirements. At the same time, during use, users also need to pay attention to regular maintenance and inspection of the equipment to ensure its normal operation and extend its service life. In addition, with the continuous advancement and innovation of technology, the performance and functions of DRS traveling wheels will be further improved and improved, bringing better user experience and value to users.