Custom Aluminum Core Polyurethane Wheel

As a new generation of innovative products, aluminum core polyurethane coating wheel is bringing a revolutionary change to the industry with its unique material combination and design advantages. This

As a new generation of innovative products, aluminum core polyurethane coating wheel is bringing a revolutionary change to the industry with its unique material combination and design advantages. This paper will deeply discuss the technical characteristics and application advantages of aluminum-core polyurethane coating wheel and how it plays a key role in improving operation efficiency, reducing cost and environmental protection.

Technological Superiority

1. Aluminium Alloy Core:The use of lightweight high-strength aluminum alloy as the wheel core material, compared with traditional iron or steel wheel core, significantly reduce the weight of the wheel, improve the handling efficiency, but also reduce energy consumption. The good thermal conductivity of aluminum alloy helps to dissipate heat and extend the service life of the wheel.

2. Polyurethane Coating: Polyurethane material is known for its excellent wear resistance, oil resistance, chemical resistance and low noise characteristics. This outsourcing layer can not only resist the erosion of a variety of harsh environments, but also reduce the damage to the ground while ensuring a high load capacity, especially suitable for use in clean rooms, hospitals, food processing and other places with strict environmental requirements.

Application Advantages

1. High Efficiency and Energy Saving: The lightweight design makes the equipment consume less energy during operation, especially in the electric handling vehicle, which can significantly improve the driving range, reduce the charging frequency, and improve the working efficiency.

2. Shock Absorption and Noise Reduction: the elastic characteristics of polyurethane material can effectively absorb the vibration during operation, reduce noise, and create a more comfortable working environment, especially for occasions with strict requirements for noise control.

3. Versatility: According to different use needs, the hardness of polyurethane can be adjusted, from soft to hard, to meet the wide use needs from indoor smooth ground to outdoor rough ground, to achieve a multi-purpose.

4. Environmentally Friendly: the recyclability of polyurethane materials and the environmental protection properties of aluminum alloy make the aluminum core polyurethane coated rubber wheel a green choice, in line with the concept of sustainable development of modern enterprises.

Application Cases

1. Automated Logistics Warehouse: In the automated storage system, aluminum core polyurethane coating wheel is widely used in AGV, stacker and other equipment, its low noise, high wear characteristics, for 24 hours uninterrupted operation provides a guarantee.

2. Food Processing Industry: In food processing workshops with high hygiene requirements, the corrosion resistance and easy cleaning of polyurethane materials make this wheel the first choice to ensure food safety and the cleanliness of the production environment.

3. Medical and Pharmaceutical: In medical and pharmaceutical environments with high requirements for cleanliness, aluminum core polyurethane coated rubber wheels have become the standard configuration of handling equipment with their low pollution and low noise characteristics.

Wrapping it Up

With its significant advantages in reducing weight, improving durability, reducing noise and so on, aluminum core polyurethane coating wheel has become an important driver to promote logistics automation and manufacturing upgrading.

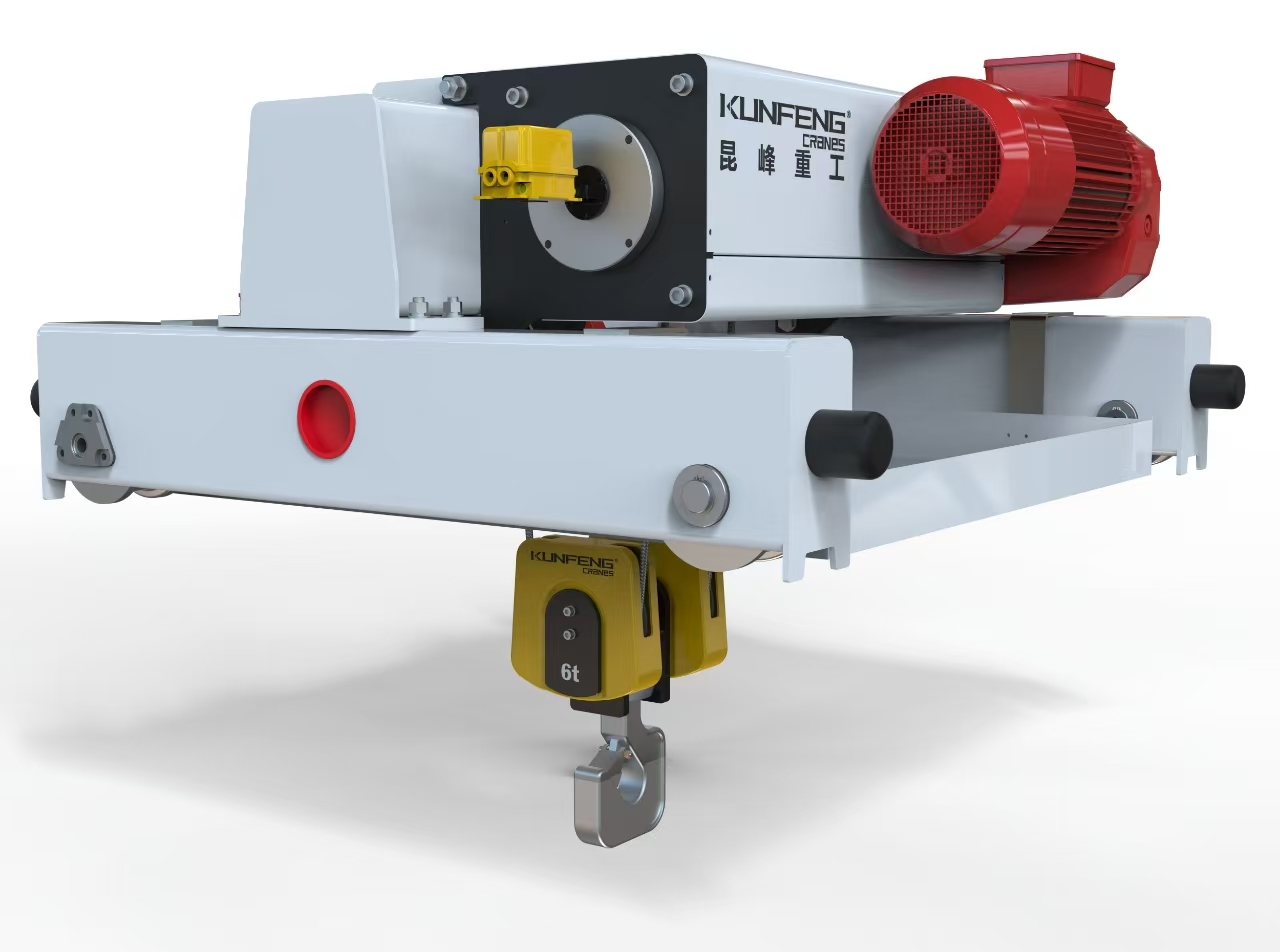

As a professional manufacturer of polyurethane coating wheels, KUNFENG CRANES can not only customize polyurethane wheels with special requirements for you, but also provide you with services such as replacement of rubber wheels. If you have aluminum core polyurethane coated rubber wheel requirements, please contact us, we will give you a quote as soon as possible!