Compared with traditional hoists, electric fiber rope hoists have lower noise, vibration and pollution, can effectively avoid the generation of metal chips and oil, and meet the strict requirements of clean rooms. It is equipped with an electric drive system, which can achieve fast and accurate load lifting, intelligent control system, support precise positioning, overload protection and remote operation, greatly improving work efficiency and safety.

Composition structure of electric fiber rope hoist

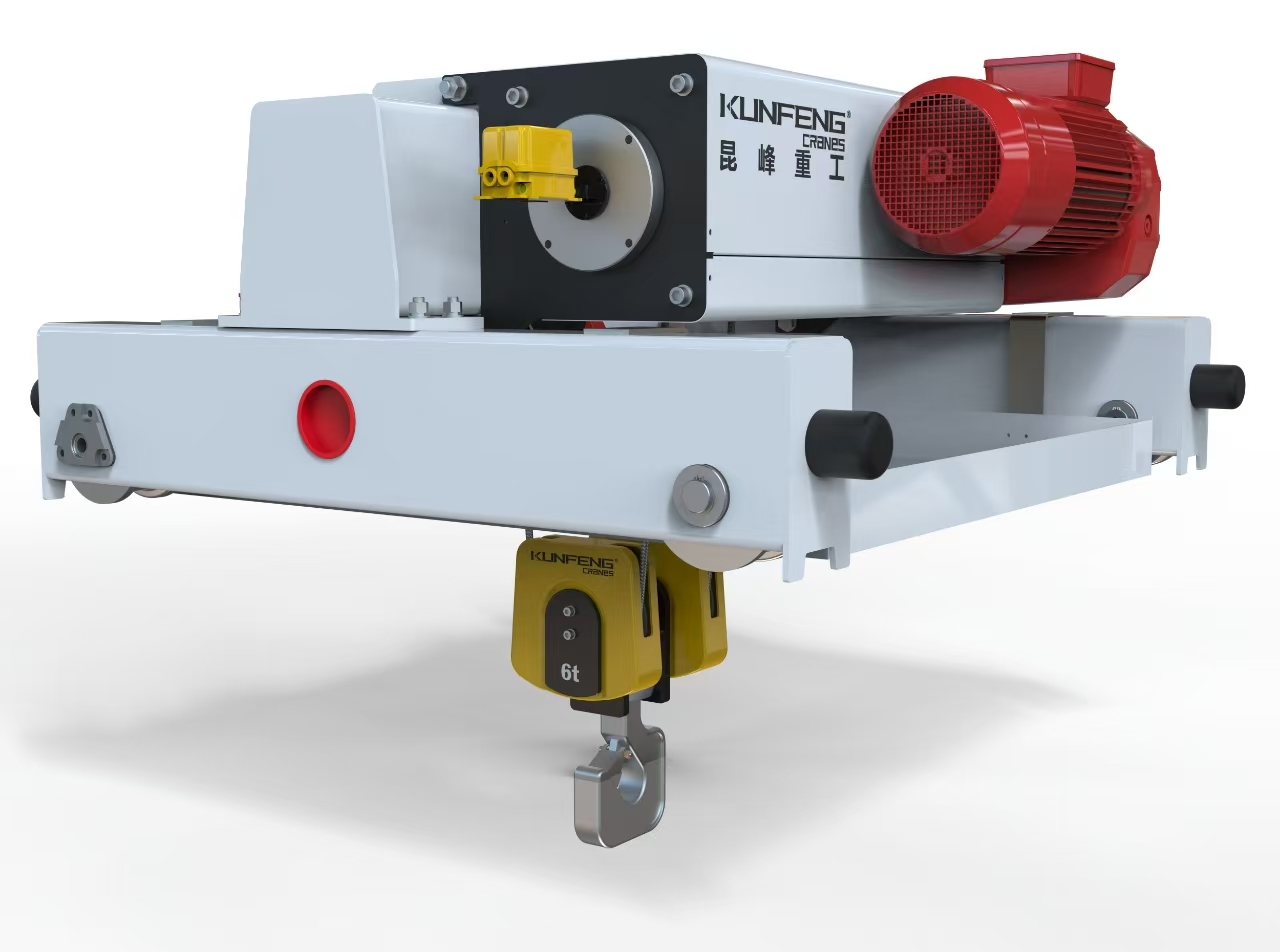

● Electric drive system: It consists of an electric motor, a reducer and a transmission device, which provides power to enable the fiber rope hoist to lift and lower the load smoothly and accurately.

● Fiber rope: It is made of high-strength synthetic fiber material with high tensile strength and wear resistance, and is light and soft.

● Hook: It is used to carry and hang loads, and usually uses corrosion-resistant materials such as stainless steel to ensure stability and safety in long-term use.

● Control system: It is equipped with an intelligent controller and an operation panel to adjust the lifting speed and direction of the crane, and realize remote control and automatic fault diagnosis.

● Limiting device: It prevents the crane load from exceeding the predetermined maximum lifting height or the lowest descent position to ensure the safe operation of the equipment.

Design features of electric fiber rope hoist

● The use of high-strength synthetic fiber rope has high tensile strength and light weight, making the crane lighter than traditional wire rope hoists, easy to install and operate.

● The fiber rope material reduces the generation of metal chips and oil pollution, and is particularly suitable for clean room environments, such as semiconductors, pharmaceuticals, and electronic manufacturing.

● Equipped with an intelligent control system, it can realize functions such as load monitoring, automatic fault diagnosis, and remote control to improve operating accuracy and safety.

● Equipped with an electric drive system, the lifting and lowering process is more efficient and stable. At the same time, safety devices such as overload protection and limit switches are provided to ensure that the work stops automatically when the load is too heavy or exceeds the limit.

● The compact design occupies a small space and can achieve efficient lifting operations in a limited space.

With excellent quality, innovative technology and reliable performance, KUNFENG CRANES is committed to providing customers with efficient, low-maintenance, and high-standard clean lifting solutions to help companies improve production efficiency and safety. Contact us to provide you with a customized fiber rope hoist solution that meets your needs for free!