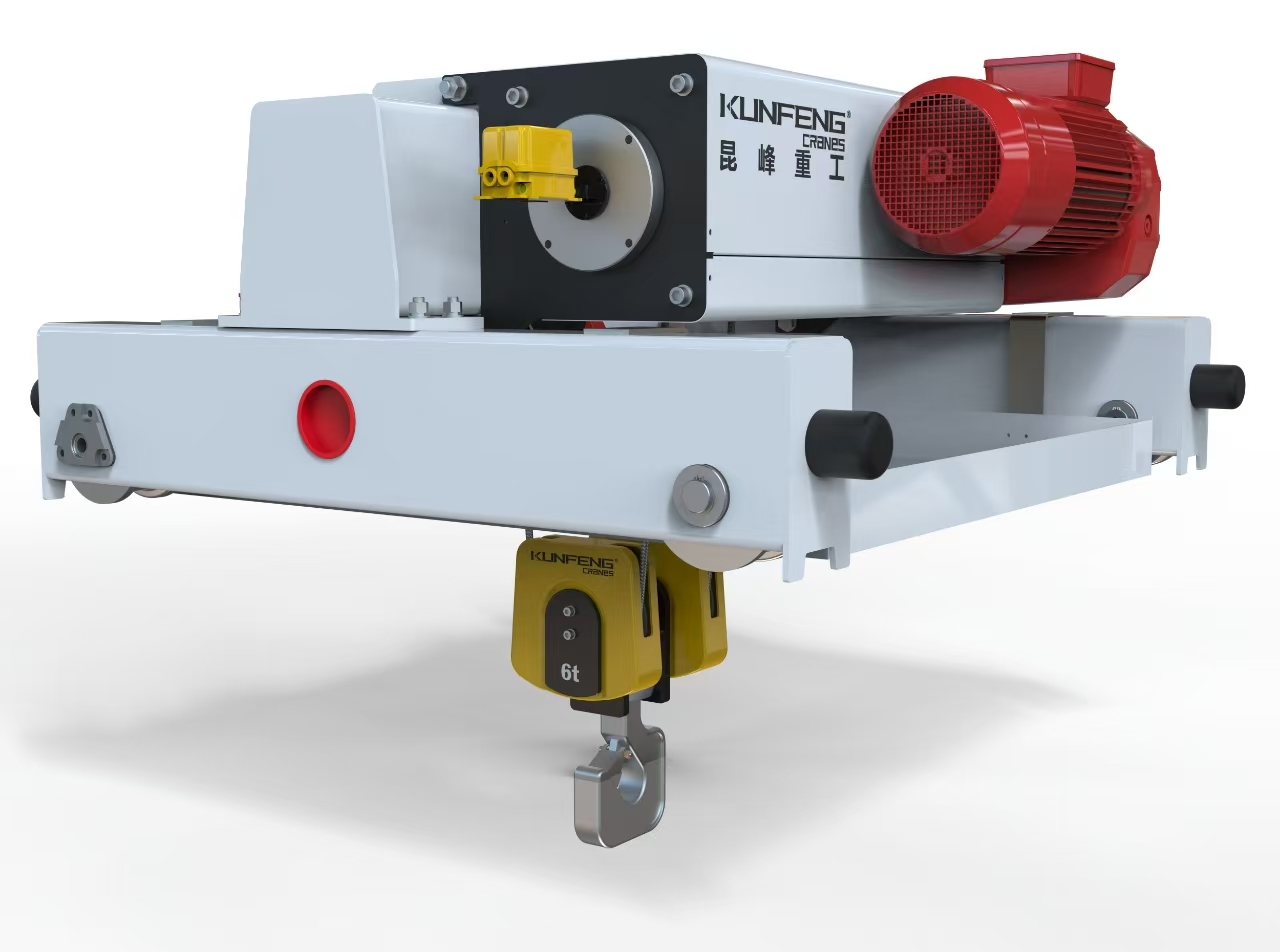

Clean Room Overhead Crane with Belt Hoist

Belt hoist clean room overhead crane is a kind of overhead crane specially designed for lifting operations in a clean environment. It usually has dust-proof and anti-pollution characteristics to meet the special lifting needs in a clean environment.

Belt hoist clean room overhead crane is a kind of overhead crane specially designed for lifting operations in a clean environment. It usually has dust-proof and anti-pollution characteristics to meet the special lifting needs in a clean environment. This kind of crane may find applications in pharmaceutical manufacturing, laboratories, semiconductor production and other places with extremely high environmental requirements.

Structure and composition:

● Main bridge: mainly responsible for the moving and lifting tasks of lifting machinery and belt hoists. The main bridge spans over the work area and supports the traveling and lifting operations of the belt hoist.

● Support structure: The structure used to support the main bridge, usually composed of columns, beams and other components to ensure the stable support and operation of the main bridge.

● Belt hoist: As part of the lifting machinery, it is used for lifting and moving goods. Belt hoist usually consists of motor, lifting wire rope or chain, hook, etc.

● Transmission device: used to drive the moving and lifting operations of the belt hoist, usually including motors, reducers, etc.

● Control system: used to control the operation and lifting operations of the belt hoist, including the operation, lifting, movement and other functions of the crane.

● Safety protection device: used to ensure the safety of lifting machinery and operators, including limit protection, load display, emergency stop and other functions.

● Electrical system: including electrical control cabinets, cables, control buttons, etc., used to provide electrical power supply and control functions for lifting machinery.

● Suspension system: used to connect the belt hoist and the main bridge to support and maintain the operation and lifting operations of the belt hoist.

The application of belt hoists on clean room overhead cranes includes the following advantages:

● Dust-proof and anti-pollution: For use in a clean room environment, its structure and material selection can effectively prevent the generation and spread of dust, particles and other pollutants, and maintain the air quality of the clean room.

● Comply with clean room standards: The design and manufacturing generally comply with the relevant standards and requirements of clean rooms, ensuring that their use in a clean room environment will not introduce external pollutants and meet the environmental requirements of clean rooms.

● Efficient and reliable: It has efficient lifting and handling capabilities, and can quickly and reliably complete the lifting and moving of goods in the clean room, helping to improve production efficiency.

● Easy cleaning and maintenance: Taking into account the convenience of cleaning and maintenance, making cleaning and maintenance work in a clean room environment easier.

● Safety: It has good safety performance, including limit protection, load display, emergency stop and other functions, which can ensure the safety and reliability of lifting operations in a clean room environment.