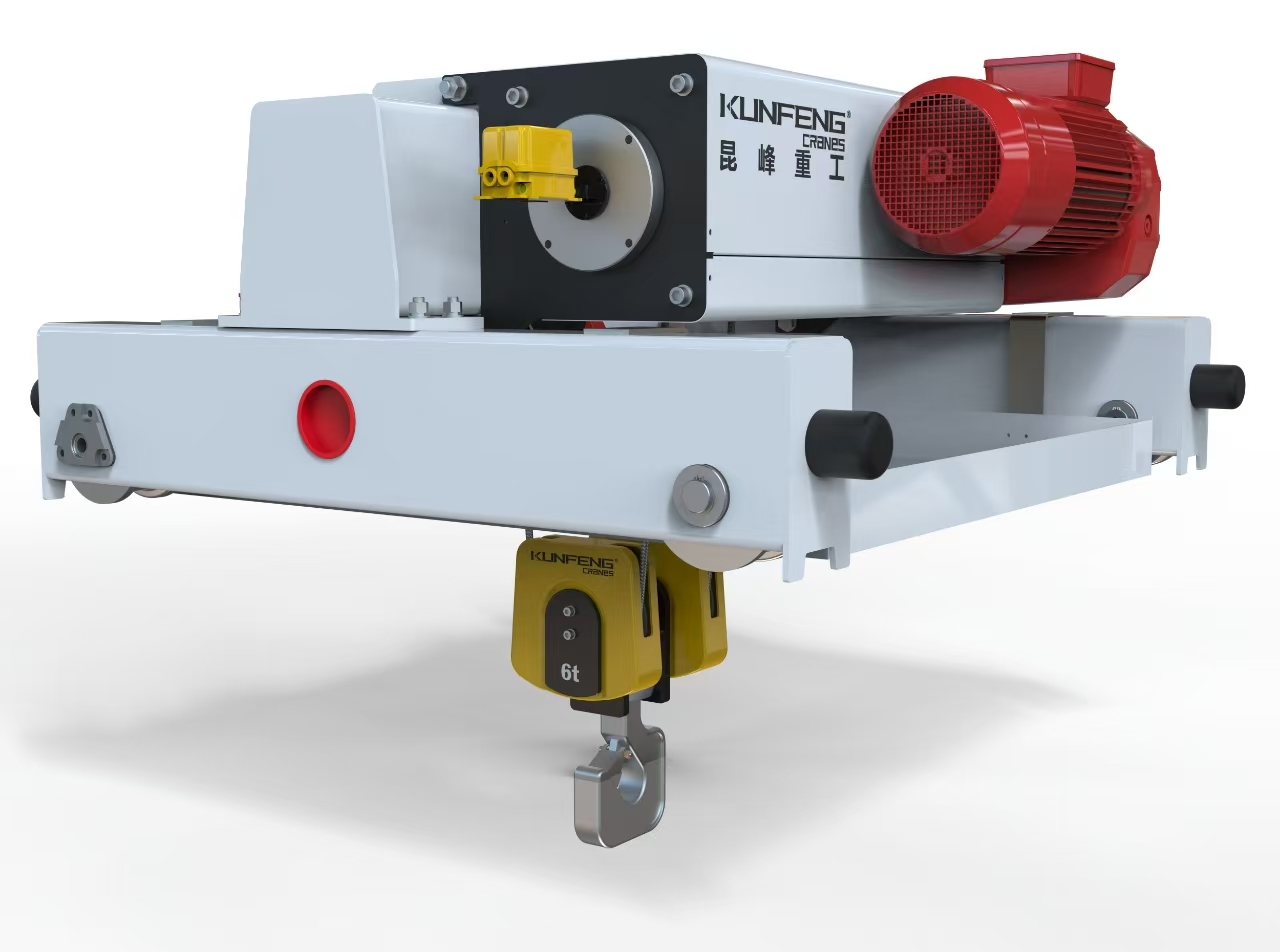

Clean Room Double Girder Underhung Overhead Crane

Double girder underhung overhead crane is a common industrial lifting equipment. Its main structure includes two beams spanning the work area.

Double girder underhung overhead crane is a common industrial lifting equipment. Its main structure includes two beams spanning the work area. The hooks suspended on the beams can move along the length of the beams to achieve control of the work area. Lifting and handling operations at various locations within the facility.

In clean room workshop applications, double girder underhung overhead crane plays an important role. The clean room workshop is a production environment with extremely high environmental requirements, and the content of dust, microorganisms and other pollutants in the air needs to be strictly controlled. In this environment, crane design and operation require special consideration to avoid contamination of the clean environment. The design of the Double girder underhung overhead crane allows it to operate at a lower height, thereby reducing the space for air movement and reducing the risk of contamination. At the same time, the structure and material selection of the crane also need to comply with clean room requirements to avoid the generation of dust or the release of harmful gases.

In the process of lifting and transporting goods, the double girder underhung overhead crane shows its unique advantages. The lifting trolley can move freely along the lifting beam, thereby achieving precise positioning of the goods. The hook or spreader on the lifting trolley can be selected according to the shape and weight of the goods to ensure the safety and stability of the lifting process. During the hoisting process, the crane operator needs to reasonably adjust the speed of the crane and the height of the hook based on factors such as the weight, shape, and handling distance of the goods to ensure smooth handling of the goods.

Main feature

The lifting beam adopts a double-beam structure, which improves the stability and load-bearing capacity of the crane.

The lifting trolley is suspended below the lifting beam, enabling low-space operation.

The lifting trolley can move freely, achieving precise positioning of goods.

The hook or spreader can be selected according to the shape and weight of the cargo, improving the flexibility and adaptability of lifting.

Product advantages

Strong adaptability: It can adapt to the lifting needs of goods of different heights, shapes and weights.

Flexible operation: The lifting trolley can move freely, and the hook or spreader can be replaced as needed, which improves the flexibility and adaptability of lifting.

Good stability: The double-girder structure improves the stability of the crane, making the hoisting process safer and more reliable.

Easy maintenance: The structure and components of the crane are reasonably designed, making it easy to carry out daily maintenance and maintenance, and reducing the cost of use.