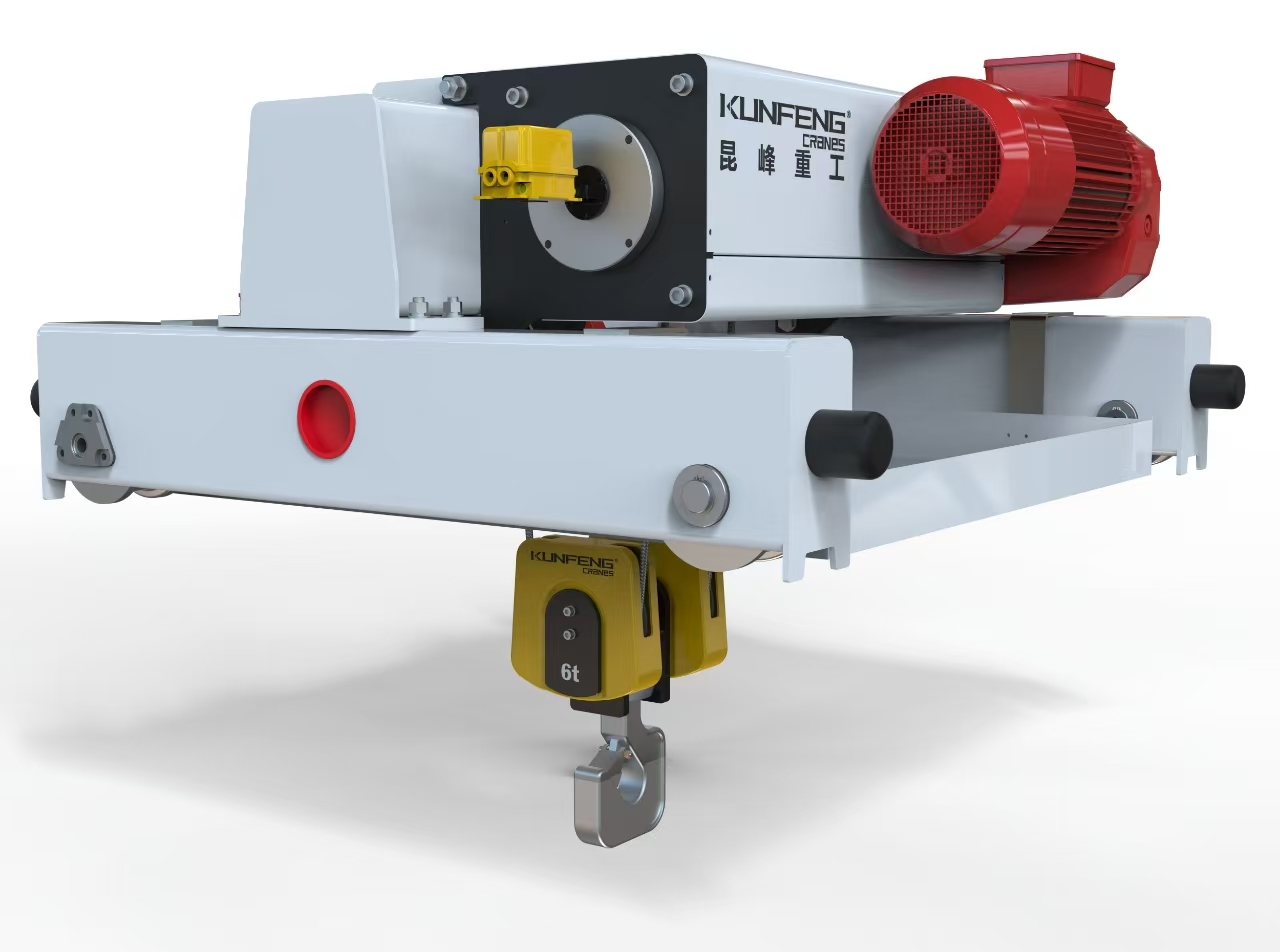

Servo Motor Intelligent Balancing Crane

The servo motor intelligent balancing crane is a device that uses servo motors and intelligent control systems to achieve object balancing and suspension operations.

The servo motor intelligent balancing crane is a device that uses servo motors and intelligent control systems to achieve object balancing and suspension operations. It is suitable for hoisting and suspending objects of a certain weight, and can maintain the balance of the object through automatic control.

Product description

● Structural features: It is composed of servo motor, sensor, controller and suspension device. The motor is connected to the suspension device through a transmission device. The controller monitors parameters such as the position, angle and weight of the spreader and the object in real time through sensors, and then controls the speed and torque of the motor to achieve balancing operations.

● Servo motor: It is the core component of the device and has the characteristics of high precision, high torque and fast response. It can adjust the rotation speed and torque in real time according to the instructions of the controller to maintain the balance of the object.

● Control system: Equipped with an intelligent control system, the motor can be precisely controlled through the controller. The controller determines the position and angle of the object based on the feedback signal from the sensor, and then calculates the corresponding motor instructions to achieve balancing operations. The control system can also adjust parameters and automatically learn as needed to adapt to different working environments and object weights.

● Balance operation: When hanging an object, the spreader and the object are kept in a balanced state through the instructions of the controller and the action of the motor. When an object tilts or sways, the control system will detect it in time and adjust the motor's speed and torque to restore balance to the object.

● Safety: Equipped with safety protection devices, such as heavy load protection, limiters, etc., to ensure safe operation. In addition, the control system can also have anti-collision and anti-shake functions to protect the integrity of the loaded items.

Functional advantages

● The weight of the heavy object is sensed in real time and the balance adjustment is performed through the motor control system to keep the heavy object in a balanced state.

● Achieve millimeter-level position adjustment to ensure accurate positioning of heavy objects and avoid collisions and damage during transportation.

● Through internal program expansion, remote control is achieved, improving work safety and convenience.

● By rising to a predetermined height along a straight path and hanging the weight from the hook, the weight can be positioned exactly where it is needed.

● It has complete safety protection measures, such as stroke limit, height limit, overload limit, emergency limit, wrong phase, lack of phase, under voltage, over voltage protection, etc.

● Achieve anti-sway throughout the entire range of lifting height, independently set the load height and activation switch, control the swing angle within plus or minus 0.25 degrees, and improve the stability and accuracy of the handling process.

● It can free the hands of workers, reduce the physical burden on workers, and reduce the risk of work-related injuries.

Prev: Pot Tending Machine(PTM)

Next: none!!