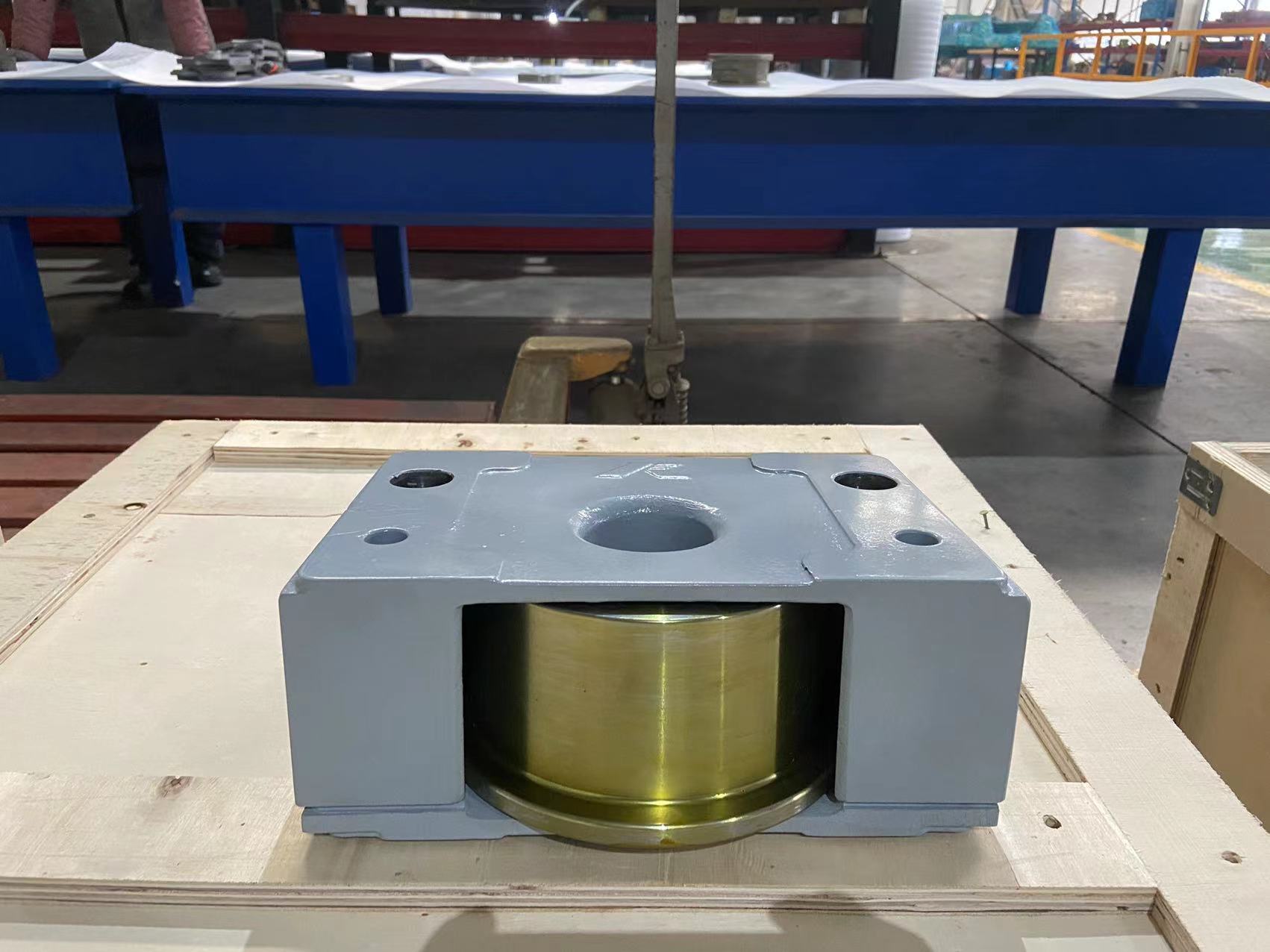

The crane drive wheel is an important part of the crane, mainly responsible for transmitting power and supporting the operation of the whole machine. It is usually made of high-strength materials to withstand heavy loads and long-term wear. The drive wheel is driven by a motor, allowing the crane to move smoothly and quickly to ensure efficient operation. Its design needs to consider load-bearing capacity, wear resistance and shock absorption effect to improve the safety and stability of the overall operation.

Parameter introduction of the drive wheel block

● Material: Generally, high-strength alloy steel or engineering plastics are used to ensure wear resistance and load-bearing capacity.

● Diameter: The diameter of the drive wheel is usually between 200mm and 800mm, depending on the type of crane and load requirements.

● Carrying capacity: ranging from a few tons to tens of tons, ensuring that it can meet the use requirements of the crane.

● Wheel width: The wheel width is usually between 50mm and 200mm, which affects stability and load distribution.

● Bearing type: Rolling bearings or sliding bearings can be selected to adapt to different operating speeds and load conditions.

● Surface treatment: Anti-rust and wear-resistant treatment, such as hot-dip galvanizing or spraying, to extend service life.

● Working temperature range: generally -20°C to 60°C, special materials can adapt to more extreme environments.

Features of crane drive wheels

● Made of alloy steel or special engineering plastics, it has excellent wear resistance and load-bearing capacity, ensuring reliability in high-load environments.

● After precise calculation and design, ensure that the drive wheel perfectly matches other parts of the crane to reduce friction and energy consumption during operation.

● The surface is rust-proofed and has good corrosion resistance, adapting to various working environments and extending service life.

● The optimized bearing and profile design reduces noise during operation and improves the comfort of the working environment.

● Effectively absorb impact force, reduce the impact on the crane structure, and improve overall stability.

● The design takes into account the characteristics of easy maintenance, which is convenient for regular inspection and maintenance to ensure the long-term stable operation of the equipment.

As a professional drive wheel manufacturer, KUNFENG is committed to providing customers with high-quality and high-performance crane drive wheels. With advanced manufacturing technology and strict quality control, our drive wheels excel in wear resistance, load-bearing capacity and corrosion resistance, and can adapt to various complex working environments. The company focuses on customer needs and provides customized solutions to ensure that each product meets specific application requirements.