Lightweight Aluminum Track Workstation Crane

The lightweight aluminum track workstation crane is an efficient and flexible material handling equipment that is widely used in production environments such as factories, warehouses, and workshops.

The lightweight aluminum track workstation crane is an efficient and flexible material handling equipment that is widely used in production environments such as factories, warehouses, and workshops. It uses light aluminum rails as the supporting structure, and realizes lifting and carrying functions through motor drive. It has the advantages of simple structure, convenient operation, safety and reliability.

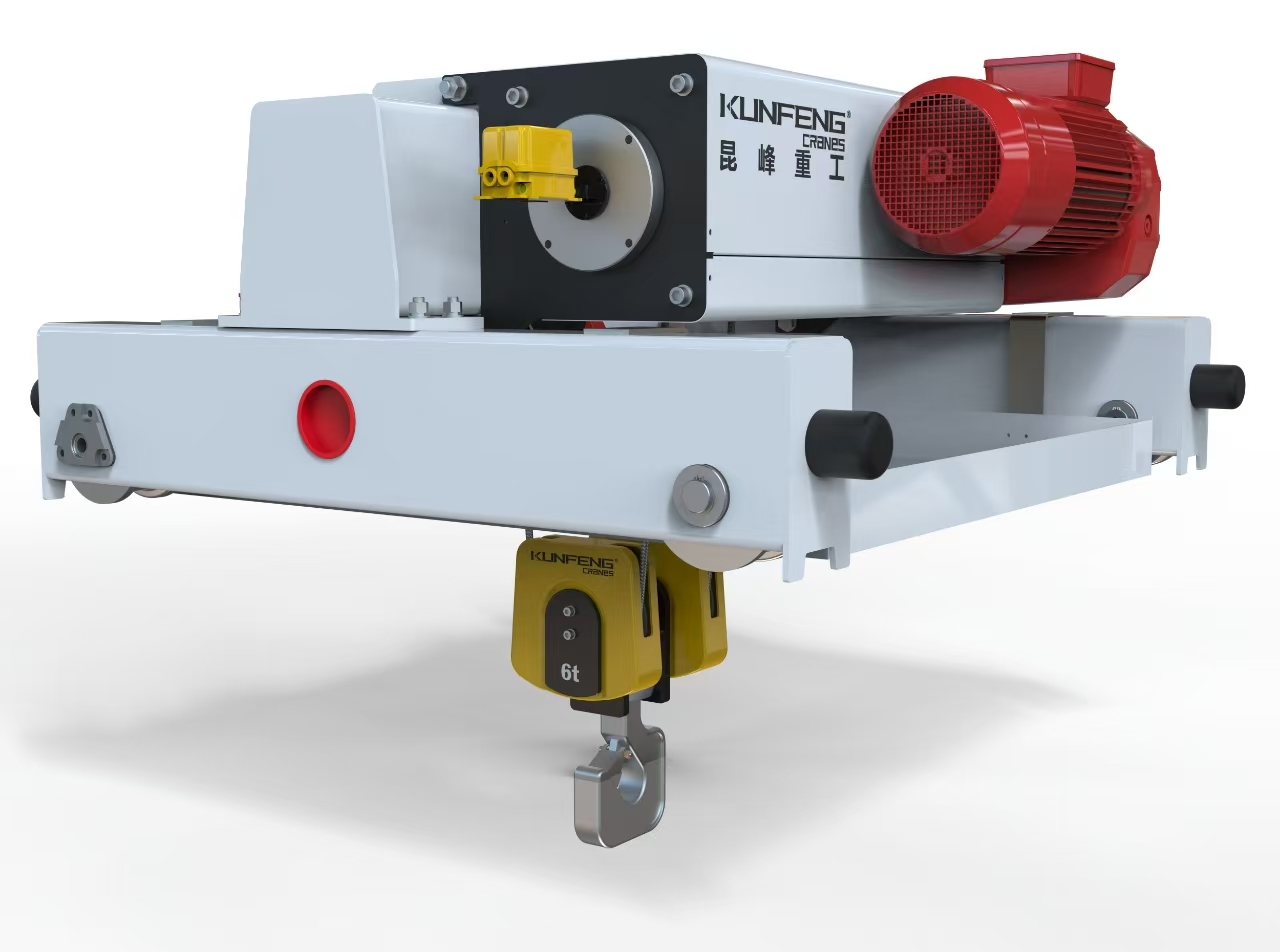

Structure and composition

The light aluminum track workstation crane is mainly composed of aluminum rail, crane body, motor, control system and other parts. As the support structure of the crane, aluminum rails are usually made of lightweight aluminum alloy materials and have the characteristics of light weight, high strength, and corrosion resistance. The main body of the crane includes beams, columns, slide rails, hooks and other components, which are driven by a motor to move on aluminum rails to achieve lifting and handling functions. The motor usually uses a DC brushless motor or a stepper motor, which has the advantages of high efficiency, low noise, and long life. The control system is responsible for controlling the operation of the motor to achieve precise control and operation of the crane.

Operating principle

The operating principle of the lightweight aluminum track workstation crane is mainly based on the function of the motor drive and control system. When materials need to be transported, the operator issues instructions through the control system, and the motor starts working to drive the main body of the crane to move on the aluminum rail. At the same time, the hook can be lifted and lowered as needed to lift and carry materials to designated locations. During the handling process, the control system can adjust the speed and direction of the crane according to actual needs to achieve precise control.

Design Features

Using aluminum rails as the supporting structure, the overall structure is simple and easy to install and maintain.

Precise control is achieved through the control system, which is easy to operate and easy to use.

Safety factors, such as overload protection, limit switches, etc., were fully considered during the design to ensure the safe operation of the crane.

The lifting height and carrying distance can be adjusted according to actual needs to adapt to different production environments.

Product advantages

It can transport materials quickly and accurately, reducing manual handling time and labor costs, and improving production efficiency.

The use of cranes to transport materials can reduce workers' labor intensity and avoid physical damage to workers caused by repetitive physical labor.

Using aluminum rails as the supporting structure, the overall space is small and the space resources at the production site can be fully utilized.

It is suitable for various production environments, such as factories, warehouses, workshops, etc., and can meet the material handling needs of different fields.

Prev: none!!