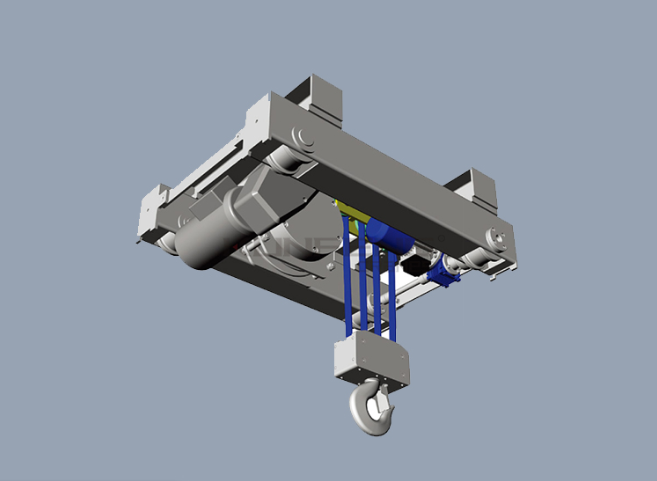

The cleanroom electric belt hoist is a high-cleanliness lifting equipment designed for cleanroom environments. It is suitable for industries with strict air quality requirements such as electronics, medicine, and precision manufacturing. The equipment uses dust-free materials and belt structures to achieve smooth lifting and lowering of materials with electric drive, avoiding dust pollution that may be generated by traditional wire rope hoists. Its compact design reduces the generation of friction particles and ensures the safety and reliability of the equipment in a clean environment.

The core production process of the cleanroom electric belt hoist is the combination of precision manufacturing and dust-free processing to ensure that the equipment operates stably and does not generate pollution in a clean environment. First, the key components of the equipment (such as the belt drive system and motor) use high-precision processing and dust-free materials to reduce the generation of friction particles. Secondly, all components are assembled in a dust-free workshop and undergo strict cleaning and sealing treatment to avoid particulate and oil pollution. Finally, the equipment needs to pass the cleanliness level test to ensure that it meets the cleanroom environment standards and meets the requirements of efficient and pollution-free use.

Advantages of clean room electric belt hoists

● The belt transmission structure and dust-free materials are used to effectively reduce the generation of particles and dust, adapt to the environment with high cleanliness requirements, and avoid the impact of pollutants on precision equipment and products.

● The dynamic control provides smooth lifting operation, and the belt structure can evenly carry the load, reduce shaking, and ensure the stability and accuracy of the equipment during handling.

● The design process uses low-noise motors and optimized transmission structures to ensure quiet operation of the equipment, which is suitable for clean room operations that require a quiet environment.

● The surface of the equipment is treated with anti-corrosion, and easy-to-clean dust-free materials are selected to ensure that the equipment is always clean during use, reduce maintenance frequency, and extend service life.

● It is suitable for different cleanliness level requirements in industries such as pharmaceuticals, electronics, and precision manufacturing. It is an ideal solution for lifting and handling materials in clean rooms.

As a professional manufacturer of clean room belt hoists, KUNFENG is committed to providing reliable lifting equipment for industries with extremely high requirements for cleanliness and safety. The company strictly follows clean room standards in product design, uses dust-free materials and precision manufacturing processes to ensure dust-free and low-noise operation of belt hoists in high-cleanliness environments. Our cleanroom belt hoists are efficient, stable, easy to operate and easy to clean, providing safe and efficient material handling solutions for industries such as pharmaceuticals, electronics and precision manufacturing.