Food Industry Clean Room Lifting Equipment

Clean room lifting equipment is used in the food industry to move and handle items such as food ingredients, finished products or packaging.

In the food industry, clean room lifting equipment plays a pivotal role. These equipment not only ensure the cleanliness of the production environment, but also improve production efficiency and provide a strong guarantee for food safety. Among them, the choice of stainless steel as the main material highlights the superior performance of clean room lifting equipment.

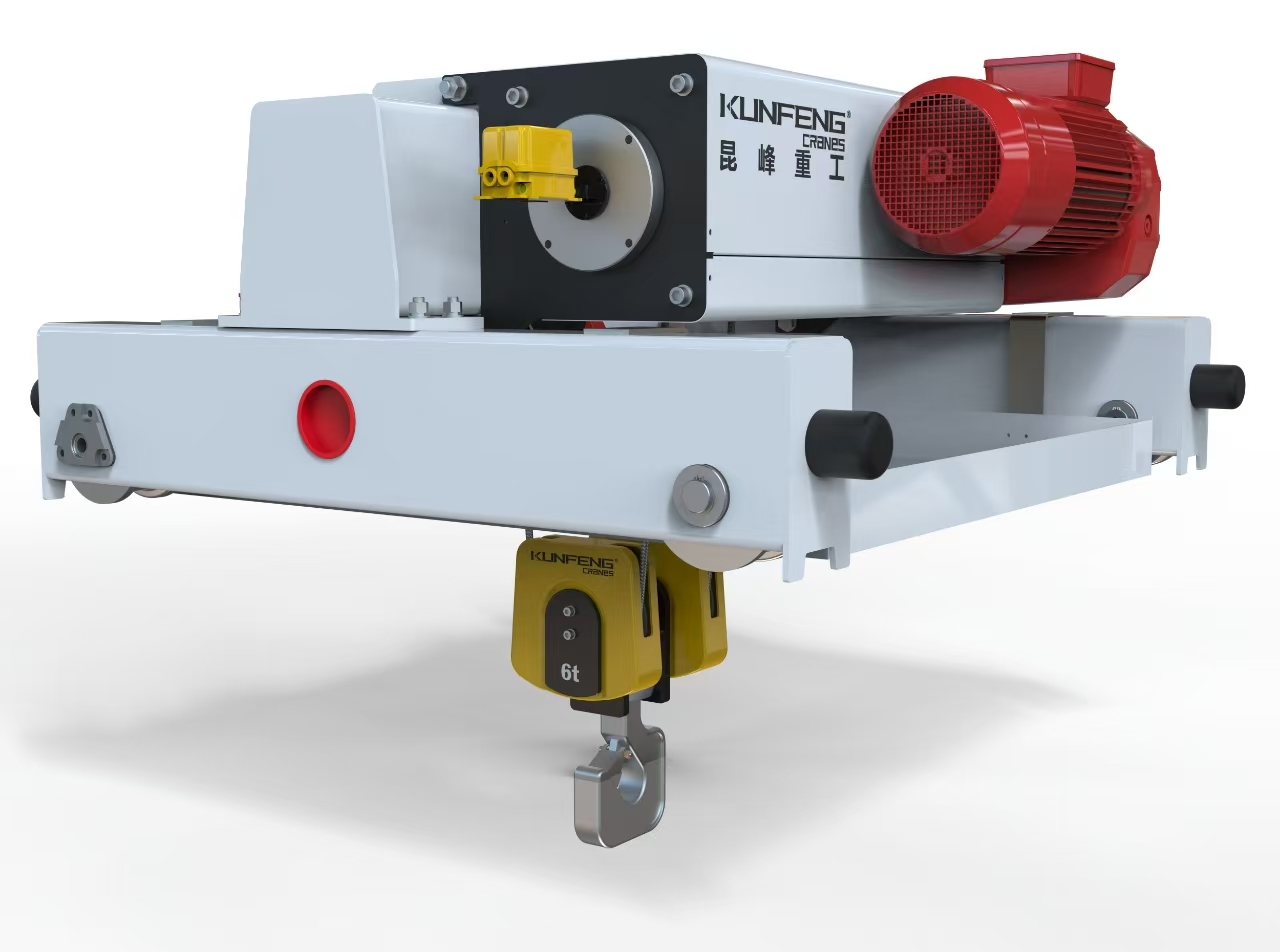

Clean room cranes adopt advanced electrical control systems and are driven by motors to achieve lifting, translation, lifting and other actions. During the lifting process, the crane will automatically adjust the speed and position according to the preset program to ensure that the items can reach the designated location smoothly and accurately. At the same time, clean room cranes are also equipped with dust-proof, anti-rust and anti-leak protection measures to effectively prevent dust and dirt from entering the equipment and ensure the cleanliness and stability of the equipment.

Why choose stainless steel as the main material

Stainless steel has high strength and excellent corrosion resistance, allowing it to maintain stability in a variety of environments. In the food industry, the production environment has extremely high requirements for cleanliness. Stainless steel has become an ideal choice for clean room lifting equipment because of its smooth surface and resistance to dust and bacteria accumulation. In addition, stainless steel does not contain harmful substances and will not pollute food, ensuring food safety. At the same time, stainless steel also has good high temperature resistance and can withstand high temperature sterilization, ensuring long-term stable operation of the equipment.

Product advantages

● The use of special designs and materials can effectively reduce the generation and accumulation of dust and particulate matter, maintain cleanliness in the clean room, and avoid contamination of products.

● Made of high-quality materials and advanced technology, it can operate stably for a long time without failure, reducing the cost of repairing and replacing equipment.

● Through the precise control system and optimized operation process, the lifting, translation, lifting and other actions of items can be completed quickly, which improves production efficiency.

● The use of advanced electrical control systems and energy-saving technology can effectively reduce energy consumption and reduce production costs.

● The corrosion resistance of stainless steel also reduces the frequency of equipment maintenance and replacement, further reducing resource consumption and environmental pollution.